Brand:-

Model:-

MOQ:100 Pieces

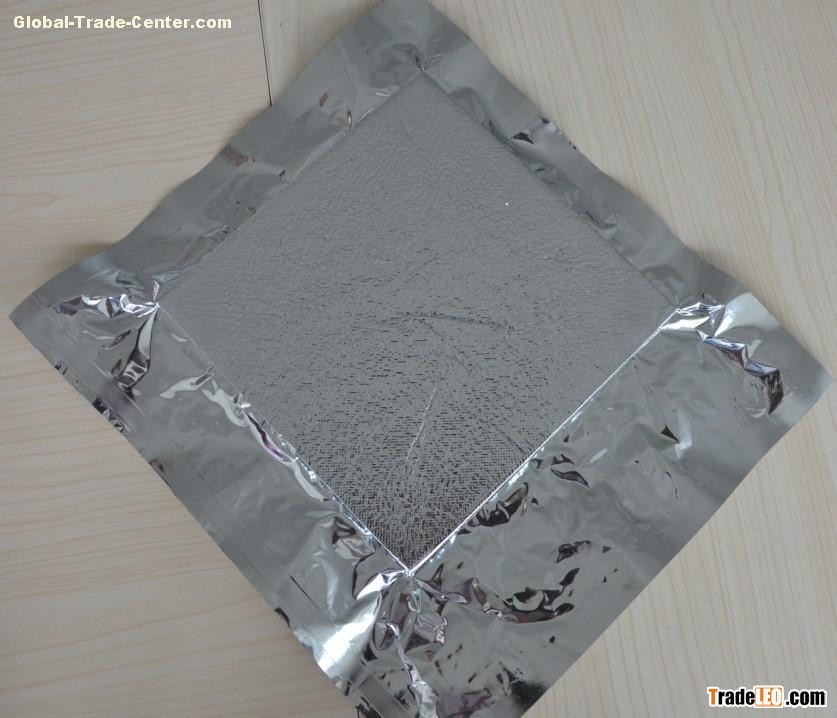

VIP vacuum insulation panel

Outline: VIPvacuum insulation panel is composited made of insulated lightweight composite nanometercore and vacuum protection surface under vacuum state, material iswith special structure, composed of three parts: core insulating material, airgetter material and high barrier functional composite film. It can effectivelyavoid heat transference, that makes thermal coefficient low to 0.005W/m.k,meantime it does not have any ODS things, with excellent environmental protectionenergy-efficient performance.It already is the most advanced efficient heat preservation material in theworld.

.

Theory and feature:

1.Tothe utmost extent to enhance inner vacuum, insulate the heat transferencethrough air convection, then reduce the thermal coefficient.

2.Toreduce the heat coming and lost heat by heat transference by core material.

3. Thehigh barrier film is composited make of aluminum foil, which can reflect heatradiation.

4. Verylow thermal coefficient: 0.0045W/m.k

5.Ultralight weight: below 4kg as standard thickness per square meter.

6.Ultra-thin application: thickness can be7-20mm, used for comprehensive field and save much using space. The 10mm headpreservation effect is the same as 10cm ordinary insulation material.

7.Lifetimecould be 50 years old.

Specification:

| Color | Silver |

| Size(Customizable) | Standard: 500mmX450mm or 600mmX400mm |

| Thermal coefficient | 0.0045W/m.k |

| Density | 180-220kg/Sq.m |

| Thickness | 10-35mm |

| Thermal stability | -50~70 |

| Wet fastness | 0%~60% |

| Length tolerance | 2mm |

| Width tolerance | 2mm0/+1.5mm |

| Thickness tolerance | 0/+1.5mm |

| Diagonal tolerance | 2mm |

| Compressive strength | Not collapse, distortion10%,(under 150KPa) |

| Lifetime | 50 years |

Applicationfield

Constructionheat preservation field:

1.Low thermal coefficient make excellent heatpreservation function.

2.It is inorganic thermal insulating material,fire-protection rating is A.

3..Mass area ratio is very low, only 4kg persquare meter when on wall, means 1/4 of ceramic, and its very safe, not easyto drop off. Widely used in exterior wall, interior wall, rooting decorationetc.

4.Convenient construction, easily tilling, save project timeand cost.

5.Innoxious, pollution-free, green andenvironmental protection, long lifetime.

6.Customized to different shape and size.

7.Customized to incorporate applicationexterior wall, interior wall, rooting decoration etc

Refrigerationfield:

(Refrigerator, refrigerated lorry, Insulated transport boxes,refrigerated container, expeditionmoving house, Insulationequipment and fittings, waterheater , electric appliances etc.)

For example:energy consumption is very important for 24 hours working refrigerator, itseasy and efficient to reduce energy consumption by using insulation material.When we use composited material made of vacuum insulation material and urethanefoam on refrigerator, not only reduce energy but also reduce the thickness ofthermal insulating layer which can enlarge the effective using space. For 242Lrefrigerator, after replaced of vacuum insulation panel, thermal insulatinglayer thickness is reduced to 3.5cm, and volume is enlarged to 260L.

Cryogenicstorage container field:

When using PU foam, container exterior size is 57cmX50cmX50cm, thermalinsulating layer thickness is 3.8cm, loading 21.8kg refrigerant, heatpreservation period is 120H.

When using VIP(vacuum insulation panel), exterior size is 33cmX46cmX28cm,thermal insulating layer thickness is 2.5cm, loading 7kg refrigerant, heatpreservation period is 200H. Container size reduced by 70%, refrigerant reducedby 68%, but heat preservation period extended by 66%, save the freight costalso.

Comparisonwith other materials:

| Material name | VIP | EPS | XPS | Polyurethane | Rockwool | Inorganic thermal insulating board |

| Thermal coefficientw/mk | 0.0045 | 0.041 | 0.030 | 0.024 | 0.040 | 0.08 |

| Fire-protection rating | A | B2 | B2 | B2 | A | A |

To know more details, welcome to contact our salesman!