Brand:-

Model:-

MOQ:-0 -

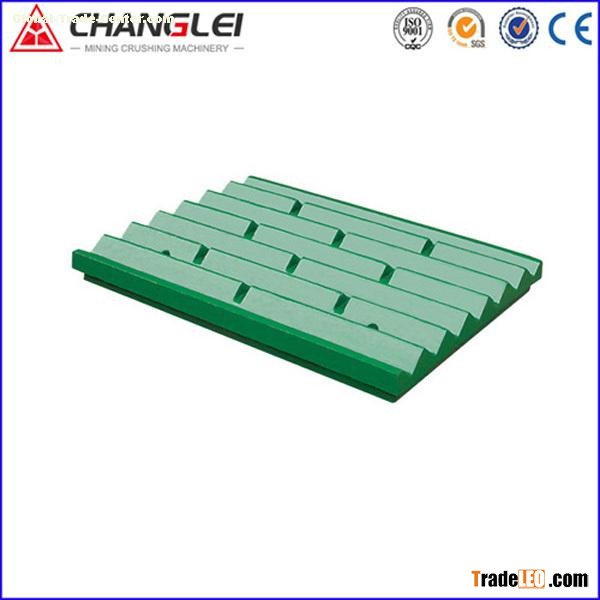

Sandvik QJ331 jaw

Suggestions choice of jaw crusher

Crusher is the use of compression and bending jaw of the two materials to achieve material crushing machinery, apparently, in the use of jaw plates subjected to more severe plastic deformation wear and tool wear. Therefore, when selecting jaw crusher material fully take into account the following factors: Sandvik QJ331 jaw.

(1) crusher specification larger block of material, the greater the degree of crushing, jaw withstand greater impact loads. In this case, the choice of material, it should first consider increasing its hardness and toughness in ensuring the jaw premise.

(2) crushing of different materials (such as granite, quartzite and limestone), jaw plate material should be different: the higher the hardness of the material, the hardness of the respective jaw plate should also be higher. Sandvik QJ331 jaw.

(3) Activities jaw and force mode fixed jaw and wear mechanisms are different. Movable jaw withstand greater impact force, therefore, we should first consider the toughness, while fixed jaw plate supported by the frame, it can give priority to hardness.

(4) When selecting jaw plate material, technical and economic effects should be considered, and strive to achieve quality and cheap, with the market competitiveness. Taking also into account the process is reasonable, easy to make manufacturers and control quality of production.

Sandvik QJ331 jaw

Material jaw crusher used is required to have a high hardness to resist plastic deformation fatigue and cutting wear, but also has a certain toughness to prevent brittle flaking or fracture. Song Yuen Industrial reminder: the actual choice of jaw plate material, we must fully understand the working conditions and wear mechanisms, rational use of jaw plate material. Sandvik QJ331 jaw.