Brand:-

Model:-

MOQ:-0 -

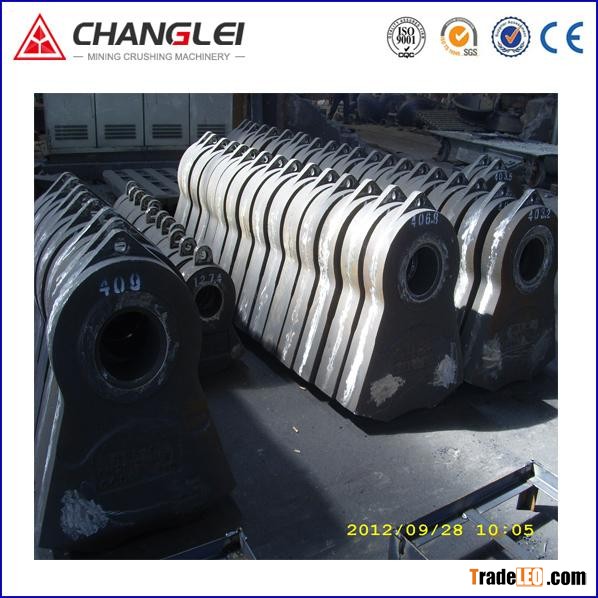

Hammer bimetallic casting

It is not allowed to grasp the opportunity to avoid pouring the molten metal caused mixed with each other in the cavity of the head with the hammer handle combining site dovetail insert separator both simultaneously pouring molten metal. Select the appropriate thickness of the separator, so that both the

The role of the two portions of liquid metal melts and they can play a relevant role in isolation is effective metallurgical bond premise. The thickness and quality of molten metal pouring concrete person, the size of pouring temperature and isolate the relevant section shall be determined by the test. An important reason why the use of separator shape dovetail bulkhead partition rather than a plane can not be secured in the case of obtaining a metallurgical bond to achieve mechanical bonding, in fact, increase the safety factor of metallurgical bonding.

Two metal bonding surface casting defects are the main factors affecting the metallurgical bond strength. The first iron was poured into the casting compound is difficult to obtain a good, easy slag generated in the bonding surface, gas larvae L and so on. Studies suggest that the reason may be formed in the liquid iron C r, Mn oxide and other elements of a more stable, not easily be restored, but as people first pouring of molten steel, the surface oxide (F e O, etc.) easily after pouring into liquid iron and other elements of C reduction, thus combining good. Further, because of lower than the melting point of molten iron pouring temperature of molten steel, such as the first pouring of molten iron is susceptible to a large area of heavy melting occurs mixed with each other, is not conducive to a combination of both, so using this production process should be the first pouring of molten steel .To avoid possible due to the separator surface

Oxidation, rust, oil, etc. affect the binding strength to deal with the front surface thereof into common use by the addition to the hammer handle

Hammer

Rust, decontamination and high-temperature baking can effectively avoid the generation of holes. The cracks are mainly due to high chromium cast iron casting stress and phase transformation stress greater role in the pre-chilling under the hammer handle, due to lack of coating thickness produced. Through a simplified mathematical model derived formulas for calculating the thickness of the high chromium cast iron coated with a certain reference value, the main production determined empirically, generally clad thickness should not be less than 2 0 r am, and should as far as possible uniform. As a result of structural constraints, can not meet this requirement, we need to take the warm-up and other measures to reduce chilling effect hammer handle to avoid cracks.

visit the website:http://www.hotcrusherparts.com/News/Hammer-bimetallic-casting.html