Brand:KAIAO

Model:-

MOQ:1 Sets

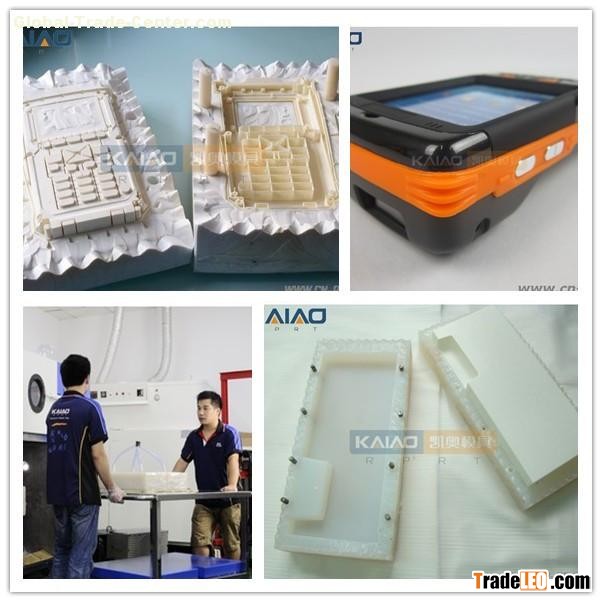

Silicon Mold Making is common cost effective Rapid Tooling method for making multiple copies of parts. Cast parts can be copied from the molds with intricate shapes and surface details, as well as with limited shrinkage and can conform to production material properties. Providing professional RP Technical support are KAIAO’s Production Specialists and Project Managers who can also offer alternative material selections and processes.

Low volume – short run productions

KAIAO Engineers can quickly make Master Patterns and within a few days can make Silicone Molds to be used for casting PU products. Compared to Plastic Injection Molding, Vacuum Casting can save time and money. The life of the Silicone Mold is directly related to the complexity of the part being cast. Silicone Molds will generally produce 15 to 30 parts before Degradation. Average cure times: (1 to 4 hours for small parts and 4 to 8 hours for big parts).

Material choices

Our material selection includes: HEI-CAST and PELNOX from Japan, and AXSON from France. The properties of the Thermoset Plastics are similar to engineering plastics: ABS, PMMA, PC, PP, PE, PA, POM, and others. We offer transparent, translucent, and opaque materials in a variety of different Shore Durometers and colorations. We also offer High Impact, High Temperature (150 degree) Fire Resistant UL94-V0 rank materials, and Glass Filled materials.