Brand:tianchen

Model:S-YZJ-750/4S

MOQ:6 Sets

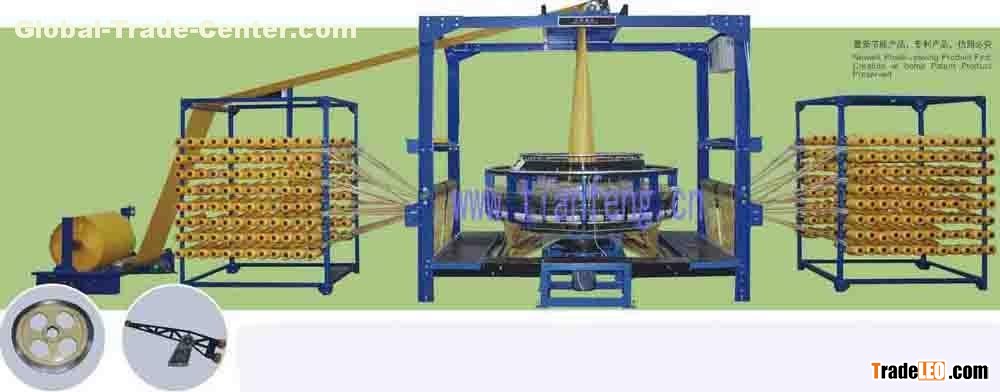

PP/PE woven bag making machine for rice and fruits

S-YZJ-750/4S FOUR SHUTTLE SMALL

1.Small cam and connecting rod rolling wheel transmission which is the most advanced technology is adopted,making it easy and stable to run.

2.Rolling transmission is adopted in entire structure instead of slide block and slide rod,which does not need lubrican and decreases the wearing part.

3.base band belt from

4.It can be configured with auto matically stop detecting unit when meeting the situation of warp/weft breaking or weft ending.The stoppage unit is sensitive and reliable.

5.It is high-efficient and energy economical.The highest rotation speed of the main motor can reach 180r/min and the power is 1.5/2.2kw,which can save 10 thousand degree electricity compared with the traditional four shuttle circular loom whose power is 4kw.

Main technique parameter

| Model | S-YZJ-750/4S |

| Number of shuttle | 4 |

| Weaving folding width | 300 |

| Max.number of warp | 640-768 |

| Revolution of main motor | 140-180r/min |

| Production capacity | 1.4 |

| Power of main motor | 1.5-2.2kw |

| Total power | 2-2.7kw |

| Weight(about) | |

| Overall dimension(L*W*H) | 8500*2300*2730mm |