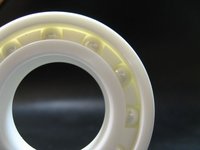

It possesses several notable characteristics such as being cold resistant, high temperature refractory, wear-resistant, corrosion-resistant, anti-magnetic insulating, high rotational in speed, and is oilless self-lubricating. It is more indispensable in extremely bad environments than other bearings, and can withstand in a variety of special conditions. The use of ceramic bearings can be applied in a wide range of industries including: aviation, navigation, petroleum, chemical, automobile, tech/electronic, metallurgy, electric power, spinning and weaving, medical supply, measurement instrument, toy, as well as ultra-high vacuum environments. Today, more and more high tech products include ceramic bearings as part of their design.

1. Zirconia (ZrO2) ceramic bearing

Application domain | Chemical industry machinery, food machinery, the sea, other water, etc. |

The general domain | Contains a PTFE (Polyteyrafluoroethylene) cage which has a higher anti-corrosive function. The environmental temperature in this usage is between 150°~ 450; groove ball bearings are suggested. |

2.Silicon Nitride (Si3N4) ceramic bearing

Application domain | This kind of ceramic bearing has a more widespread breakthrough in the material application. It has a stronger degree of hardness - almost up to HRC80, and the tolerance of high temperature also reaches to about 800 . Therefore, its surface is smooth and adamantine, and also has the self-lubricating ability. |

The general domain | High vacuum environments, high-speed spindle machines, grinding machines, dental drill machines, measuring appliance machines, model airplanes, ice skates, etc. |

3.Silicon Carbides (SiC) ceramic bearing

Application domain | In extremely bad environments and special places. For example, in an extremely high temperature environment (suggestion: groove ball bearings) it can withstand up to 1300 . Also, in a high corrosion chemical agent (suggest using a PTFE cage) to have a longer usage life, because its hardness reaches up to HRC90. |

4.The ceramic and steel mixed bearing

Application domain | Because of the characteristics and attributes of ceramic, there are many limits in the processing process, as well as the difficulty of manufacturing; therefore the price is higher. Thus, the mixed bearing was created, especially the type where the ball is ceramic and the inner and outer ring are bearing steel. They are used mostly in high speed and high accuracy required domains. | |

Ceramic ball and the inner-outer ring stainless steel (SUS440) can preventcorrosion, has a high lubrication and wear-resistant effect. | ||

The inner-outer ring Zirconia, and the Silicon Carbides ball mixed bearing. | ||

The mixed type bearings above are suitable for ice skates, model airplanes, electrically operated toys, etc. | ||