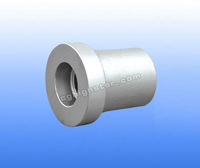

OEM forging part guide sleeve :

We are one of leading exporters of all kinds of forging products and machining products. And we are enjoying an excellent reputation through more than 5 years' business experience.Our products enjoy a great popularity at home and abroad due to our highest quality ,competitive price and excellent designs.

Product detail:

Products name: forgings, forging products, auto forging parts

Material: Carbon Steel, Stainless Steel, Alloy Steel, Aluminium, Copper

Process: die forging / free forging / cold forging / hot forging

Certificate: ISO9000; TS16949 Certificate

Surface treatment : Black oxide finish; Sand blasting, Polishing,Zinc Plated, Hot Dip Gal.,Copper Plated,Nickle Plated.

Standard; GB,ISO,ASTM,JIS,DIN,BSI

Max block size is 500×380×250mm

Unit weight: 1KG~15KG

Package: Sea-worthy PLYwooden boxes Or as per customers requirements.

Technical:

Forging method: Ingot-CNC Molding- Die forging-Pressure-Heat treatment-Surface treatment

Country of Origin China(Mainland)

Forging Material:

High Strength Alloy Steel,Alloy Steel,

34CrNiMo,42CrMo,35CrMo 20CrMnT

Carbon Steel:S45#,S35#,S20#

Stainless Steel:SUS316L,SUS316,SUS304

Surface treatment: anodized, descale, Shot-blasting

Forging capacity: 100,000pcs per month

Main process equipment: Medium frequency induction furnace;3T Electro-hydraulic forging hammer;1000~ 2500T screw press;

Vertical CNC milling machine; Radial drilling machine

Trade terms

Minimum Order 50-100 pieces

FOB price Contact us

Payment terms :Telegraphic Transfer, Western Union

Packing and shipping:

1.Prevent from damage.

2.As customers' requirements, in perfect condition.

3.Delivery :As per contract delivery on time

4.Shipping:As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant..

Quality Control:

1.Chemical Composition confirm after Ingot

2.Hardness after Heat Treatment

3.Final Dimension Check

Quality Assurance document

1.Item Testing Plan will be submit to customer in 1 day after contract signed.

2.All the Q.A document as per Client Requirement will be submitted before final product shipped out

Service

•Drawing: we can translate your original drawing ,offer best suggestion on design

•Quality: we have full set quality control system to guarantee the best quality.

•inspection: inspect in house ,all our products must be checked 3 times before packing

If you are interested in my offer, please send me your detailed information such as your drawing or detailed specifications, chemical composition requirement, etc. and you will get our quickly reply!