Brand:rsggr

Model:rsggr1

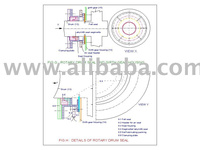

RIM -SEALING OF TUBE MILLS USED IN PULVERISERS OF THERMAL POWER PLANTS

The most critical item in the lubrication scheme with oil lubrication, is the Rotary drum end seal. The general arrangement of the seal in two views, is given in Fig G. Fig H, gives the half-sectional view of the arrangement, with part numbers of the retrofit assembly. The seal assembly, designed as segments, incorporates four stages of sealing, including the existing felt sealing, along the rim diameter of the drum. The labyrinth segments(8.4), and self-lubricating packing(8.5), have overlapping split lines along the thickness, as shown in assembly, so that the joints are given a break, and are not directly exposed to the leaking fluid. The axial pressure exerted on the labyrinth segments, through the self-lubricating packing material(8.5), keeps the labyrinth lips in intimate contact with the rotating drum rim, ensuring adequate sealing action. The seal air flow with adequate differential pressure, gives a dust-proof pressurized air curtain in the annulus, and removes the frictional heat from the contacting interface of the seal members, thus minimizing wear, and increasing the life of the sealing members. The total arrangement ensures leak-proof sealing of the interface, both during static and dynamic conditions.