Model:TC-A

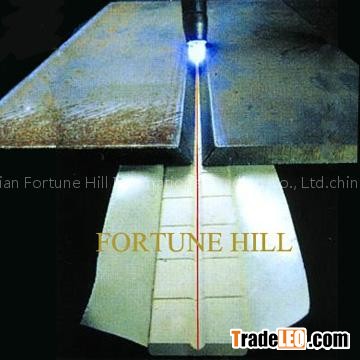

In steel plates and pipe welding industry welding joints are achieved from a single side using a ceramic backing tape. The ceramic backing tape is like a mould to pour metal in, but in this case the electrode will fill that mould. When ceramic backing tape is used it allows for full joint preparation and outstanding weld quality. This is in return gives full control of the shape and penetration of the back side of the weld. once the weld is finished, the ceramic tape is simply peeled off, and thrown away. The great thing about using ceramic backing tape is that it is just like welding an open root butt joint, but requires much less skill. Ceramic backing tapes convert two side welding process into single side welding process.

Description

1. a ceramic backing material for welding

2. get perfect penetration without material for welding

3. get perfect penetration without cracks or hairline opening

4. saves welding cost approx. 40% & time approx 50%

5. suitable for ship building, marine facilities, plants and other steel structures

6. widely used for one side welding technique such as CO2 semi-automatic welding and automatic welding.

Feature

1. Ceramic backing is a fine ceramic product composed of adequately mixed natural inorganic substances (kaolin, talc, alumina, magnesia etc.) that are heat-treated at high temperatures of 1,350~1,400 degree of centigrade span.

2. Since ceramic backing is heat-treated at high temperature, its shock resistance to rapid heating and cooling is excellent (coefficient of thermal expansion is 1.85 - 2.5 x 10-6 at 1,000 degree of centigrade) and maintains superb stability against the high temperature created good beads on the back side.

3. Ceramic backing has excellent characteristics of ceramic such as anti-acid, anti chemicals, anti-corrosion and also caused no change or reaction of steel at the time of welding.

Advantages

1. No back side grinding required.

2. Saves cost / Saves time.

3. X ray quality back beads.

4. No scope for rejections, failure to macro/ micro examination & radiography. Eliminates defects and reworks, improves quality.

5. Deposit more weld metal for full penetration. Minimize rework & reweld.

6. Useful for different types of weld joints, i.e. single & double V butt joints, dished ends / shell to manhole / hand hole, tube plate to shell etc

7. No oxidation, No pollution, No hydrogen inclusion.

8. Ensures enhanced safety, Comfort & Best work environmental condition to the Welder & Fitter.