Trust Tooling isgood plastic mould maker in China ,we offer various plastic moulds for all overthe world. And 0 defect reported from Customer.

Oursatisfied customer include Ikea, Walmart, Oates,etc. From Europe to Middle eastCountries.Price is depend on the quality .But service is all the same.

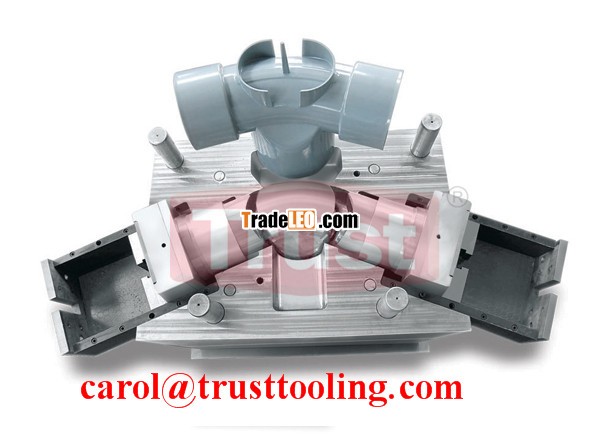

Plasticpipe fitting mould,such as tee mould,elbow crate mould,socket mould,PPR fittingmould with 4 cavity, Y type mould,etc We had rich experience to offer you goodquality plastic pipe fitting moulds.

Basicallyinformation about 2 cavity crate mould:

| Cavity:Two |

| Injection Machine:500T |

| Product Material:PP |

| Product Size: |

| Mould Size: |

| Steel:2738HH,718HH |

| Gate:hot runner or Cold runner

|

There are three levels of plastic crate mouldquality for your option.

| Option | Level A quality(Highest Level Quality) | Level B quality(Middle Level Quality) | Level C quality(Lowest Level Quality) |

| Mould base | LKM,45# Steel | 45# Steel,self-made | 45# Steel,self-made |

| Core/Cavity | S136+Becu | 718H | P20 |

| Slider/Insert | S136 | 718H | P20 |

| Mould spare parts | SKD | standard,China | standard,China |

| Hot Runner | YUDO, Korea | Guangdong China | Guangdong China |

| Mould Life | 800,000-1,000,000 shots | 500,000-800,000 shots | 300,000-500,000 shots |

| Cycle Time | 40s | 55s | 60s |

Attention pls:

Price varies in different quality level. When yousend us the mould inquiry, please offer the following information:

1) Qualitylevel you choose: Level A/Level B/Level C

2) Photo

3)Dimension: L*W*H

4) Speicalorder acceptable!!!

FAQ:

1: what is Trust tooling company deal ?

A:we make different kinds of mould and both make plastic productinjection

2.What other website we have

B:www.trusttooling.com

www.trustcommercial.com

www.trustinc.com

3. howabout certificate?

C:We will make 100% full inspection and provide the inspection reports.

4. how to contact with me in effectiveway?

D:you can contact me on skype,QQ,Email,whatsapp wechat ,alibaba online TM

also send inquiry with 3D drawing or 2d drawing ,or original sample withsize ,and tell us your details requirements ,

like needs to use what material,mould need to make how many cavities

5.Is itpossible to return the money if the quality is not good?

E:This has never been occured right now ,as we treat the quality asour key of development.Quality and service is everything for us.

Companyinformation:

Sample Room

Companyprocessiong workshop

Our pipe fitting Mould

Packaging &Shipping

We can offer the complete package from concept to delivery; arrangingeverything up until the point your product arrives at your own door ordistribution hub

Delivery can be offered.

- Utilizing your own freight-forwarder

- FOB to a port in China

- CIF to a port near you

Whether you have your own freight-forwarder or you would like us to organizeshipment; whether you require delivery FOB to a port in China or CIF to a portnear you, we are happy to quote and supply whichever way you choose. Please feel free to discuss all options with us

Our Service :

Pre-sale service:

Our company provide good salesman for professional and promptly communication

In-sale service:

We have strong designer teams, will support customer R&D, If the customer send us samples, we can make product drawing and do the modification as per customer request and send to customer for approval. Also we will accord our experience and knowledge to provide customers our technological suggestions.

After-sale service:

If our product have quality problem during our guarantee period, we will send you free for replace the broken piece; also if you have any issue in using our moulds, we provide you professional communication

Quality Control

For the Q/C of mould, there are 3 steps:

1.Mould Material Q/C

- Mould Steel Checking(Hardness, flawdetection)

- Mould Standard Spare PartsChecking(hardness, size, flaw checking)

2. Mould Making Process Q/C

- Design checking (part design, mould design,mould engineering drawing)

- Each part of mould's size checking aftermachining according to 2D drawing

- Mould testing(check mould runningcondition)

3.Check with customer's requirement againbefore mould shipping.

Maintenance

a) Whenthe mould is vacant, spray the anti-rust oil

b) Toclean the gate and cooling system regularly

c) Avoidto use recycled material if the mould is suitable for virgin material only