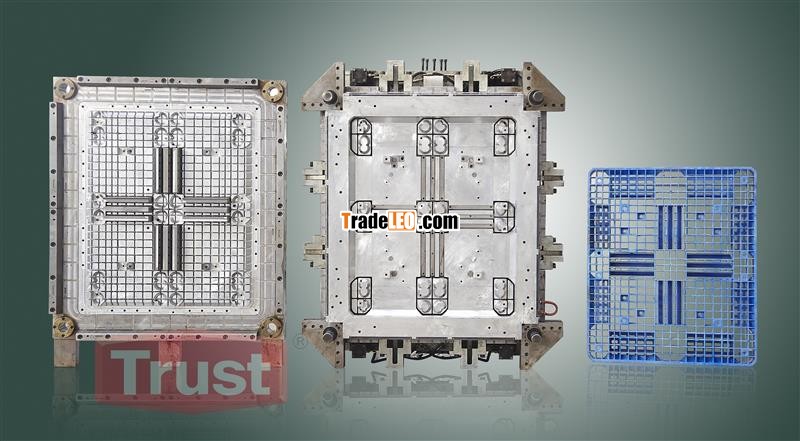

Brand:Trust Tooling

Model:customized

Trust Tooling company is professional and skillful mould maker, we are not only can offer injection moulds ,but also Structure foam moulds.

Many customers interested in the structure foam molding products,like pallet, container, bin ,carts,etc.But they dont have accordingly machine for production,so they can not come into the field.

But Trust Tooling can offer structure foam moulds,and also provide the structure molding service,which means you make mould from us and we help make production and package the product for you .As we also the molding manufacturer for IKEA, OATES,WAL-MART,so about the package we are good at it.

Let me explain what is the structure foam molding advantage.

Structural Foam – Benefits

There are many benefits in producing products using Structural Foam technology:

1) Part weight can be reduced between 10% and 30%, resulting in lower material costs without affecting structural integrity

2) A large shot size capability of up to 150 lbs (68 kg) per shot. Larger products can be designed to combine many smaller parts, with different functions, into one part to reduce cost and increase efficiency

3) Low pressure molding uses less energy per pound of plastic and less raw material in the finished product

4) The low pressure process is better suited to using recycled materials. Many Structural Foam plastic products are made from 100% post consumer resin meaning more plastic is diverted from landfill. All Structural Foam plastic products are 100% recyclable

5) Low pressure Structural Foam machines have multi-nozzle capability, meaning that multiple molds can be run on the same press at the same time, reducing cost and reducing lead times