Brand:Apollo

MOQ:1

Quantity:6

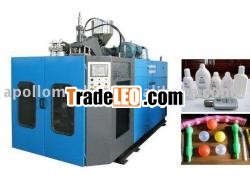

ABLB45 full automatic extrusion blow molding machine wasspecially designed for making plastic water bottles,medicalbottles,oil bottles,plastic balls ,suction tubes and other smallplastic containers not over 2L.

Main parts of Machine | Picture | Explanation |

Mould Open and Close machanism |

|

Single station Open and close the mould |

Oil Pump |

| Oil pump From TaiWan JinShun use to drive the machine |

Computer control system (PLC) |

| Japanese Mitisubishi PLC

Used to control all electrial components and touch screen |

Screw and fan |

Screw diemeter 45mm Fan used to cool the screw. | |

Die head |

|

Double die heads available More fast and reliable output |

Electric Cabinet |

| This part is the full electric components of the machine |

The main components of the machine. ( ABLB45 )

electronicparts |

|

Name | Trader |

Micro computer control system | Japanese MITSUBISHI |

Temperature Controller | TAIWAN YANHUA PID |

Auxiliary Relay | OMRON |

contactor | Schneider from France |

Electric motor | Three phase 220V or 380V |

Power Source | TAIWAN MEANWELL |

Transducer | TAIDA FROM CHINA |

hydraulic parts |

|

Name | Trader |

Oil pump | TAIWAN HIGH-TECH |

Valve | JAPAN YUKEN |

Oil pump and connection | JAPAN YUKEN |

Sealed part | HALLITE |

air control system |

|

Name | Trader |

Cylinder | AIRTAC |

Air Valve | FESTO |

Technical Parameters: ( ABLB45 )

Max. Product volume | 2L |

Out put capacity | 500~600pcs/h |

Screw diameter | 45mm |

Screw L/D ratio | 24:1 L/D |

Screw drive power | 10 KW |

Screw heating capacity | 2.6 KW |

No.of heating zone | 3 zones |

Output of HDPE | 35 KG/H |

Oil pump drive power | 4.8 KW |

Clamping force | 32KN |

Max.size of mold | 80-350mm |

Mold stroke | 250 X 320mm |

Max.die diameter | 80mm |

Blowing pressure | 0.6 mpa |

Air Volume | 0.4M³/MIN |

Cooling water pressure | 0.3mpa |

Water consumption | 30 L/MIN |

Size of Machine | 2.6x1.4x2.2m |

Weight of machine | 2.8 ton |

Full-automatic extrusion blow moulding machine