Description:

polyester dryer fabric for paper making1.ISO9001:2008

2.high quality and long useful life

Technical data

| Name | BGW22708 |

| Material&Diameter | Warp:polyester monofilament yarn(0.38mmx0.58mm) |

Weft:polyestermonofilament yarn(0.35mm;0.70mm) | |

| Weight(g/m2) | 1170 |

| Thickness(mm) | 1.60 |

| Density(counts/10cm) | Warp:220 |

| Weft:125 | |

| Airpermeability(L/m2.S) | 2046 |

| Burstingstrength(N/5x20cm) | Warp:6985 |

| Weft:8030 | |

| Elogation(%) | Warp:28.57 |

| Weft:39.9 |

Usage

BGW22708:applicable for dryer ofpaper making and filtration.

Advantage

Our polyester flat dryerfabric BGW22708 is made by red flat polyester yarn, it canincrease the contact surface of our fabric and the paper, so itwill promote the heat transfer between the paper and dryer,when steam flow through our fabric, it will decrease theprobability of steam condensation, and improve the dryingefficiency. our flat dryer fabric''s use flat yarn, so the surfaceof our fabric is very smooth, compare with the fabric made byroundness yarn, the wire marks is more slight in dryer process. ourpolyester flat dryer fabric select the hydrolysis resistancemonofilament yarn, it can prominent enhance our fabric''sservice life and increase our customer''s economiceffectiveness.

we always use selfpin joint and endless joint for our polyester flatdryer fabric, it''s easy to install in all kindsof papermaking production line, we also do resin edgereinforcement for our fabric, so our quality is perfect. and wingood reputation from our customers all over the world.

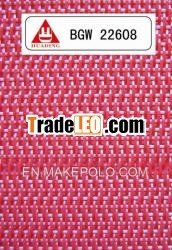

Product picture

1.our polyester flatdryer fabric BGW22708

2.our BGW22708 and other polyester fabrics whichcan also use for dryer of paper making

Our joint and seam

1.self pin joint(self pin jointis autofit for our BGW22708)

2.we have four kinds ofjoint

(endless joint--self pinjoint--clipper joint--spiral joint)

Resinedge reinforcement

(our customer can select yellowor blue color glue for their edge reinforcement)

Conducting barreinforcement

(sometimes, our customer willrequest us making conducting bar to adjustment belt in theirmachine)

Network primer

(when our customer install ourbelt in their production line, they use our networkprimer to traction equipment)

Our workshop andequipment

(we have advanced equipment and manyprofessional engineers)

Our productionprocessing

(warping--wearbuckle--knitmesh--once heat setting--seaming--twice heatsetting--edge treatment--package--finish)

Our package

(we always use wooden box for export)

Job site and productionline

(our customer use our polyester dryerfabric for their production line)

Our certificate

(our products have passed thequality system authentication of ISO9001:2008)