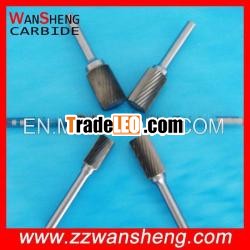

Description:

Dental Carbide Burrs (Type C) with best quality1. High production efficiency

2. Long service life

Tungsten CarbideRotary Burrs

Features and directions for use:

Tungsten Carbide RotaryBurrs is alsocalled Carbide high speed cutter, or Carbide mould cutter. Incomparatively developed countries in the world the files havealready found wide application and have been regarded as animportant means for raising production efficiency and realizing themechanization in bench work. The file, as a necessary tool forfitters and repairmen has gradually gone popular in our Country inthe recent years.

TungstenCarbide Rotary Fire finds very wind application in case such asfollows:

lCapable ofmachining various metal (including different quenching steel) andnonmetal materials (such as marble, jade and bone) with hardness upto HRC70;

lTo replace smallshank grinding wheel in most instances, no dust contaminationproduced;

lHigh productionefficiency, several tenfold the manual operated file, and 5-10 foldthe small shank grinding wheel;

lLong servicelife, ten times the high speed steel tools and 200times the smallgrinding wheel in durability;

lEasy to handleand operate, safe and reliable, able to reduce labour intensity andimprove working condition;

lHigh economicbenefit may have a 10% reduction in comprehensive processcost.

There are manytypes for your choice:

Type A--Cylindrical

Type C--Cylindricalball

Type D--Spherical

Type E--Elliptic

Type F--Areround head

Type G--Arc point

Type H--Torch shaped

Type L--Conical round head

Type K--60° Conical

Type K--90° Conical

Type M--Conical point

Type N--Upconing

Type S--Conical flat head

Type T--Semi-Circular

Type W--CylindricalSemi-Circular